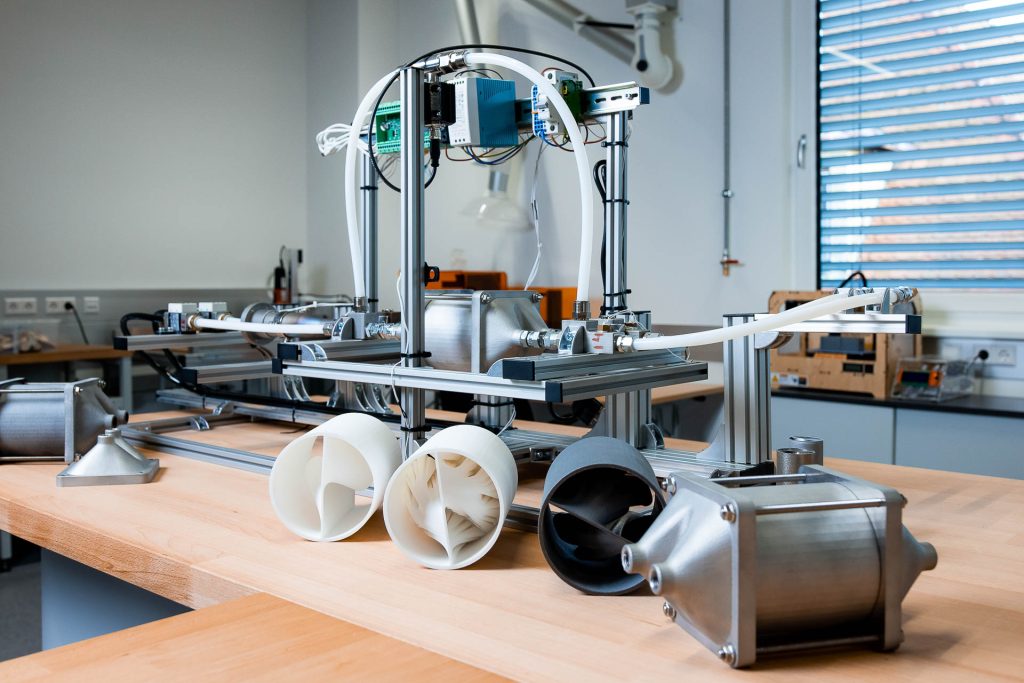

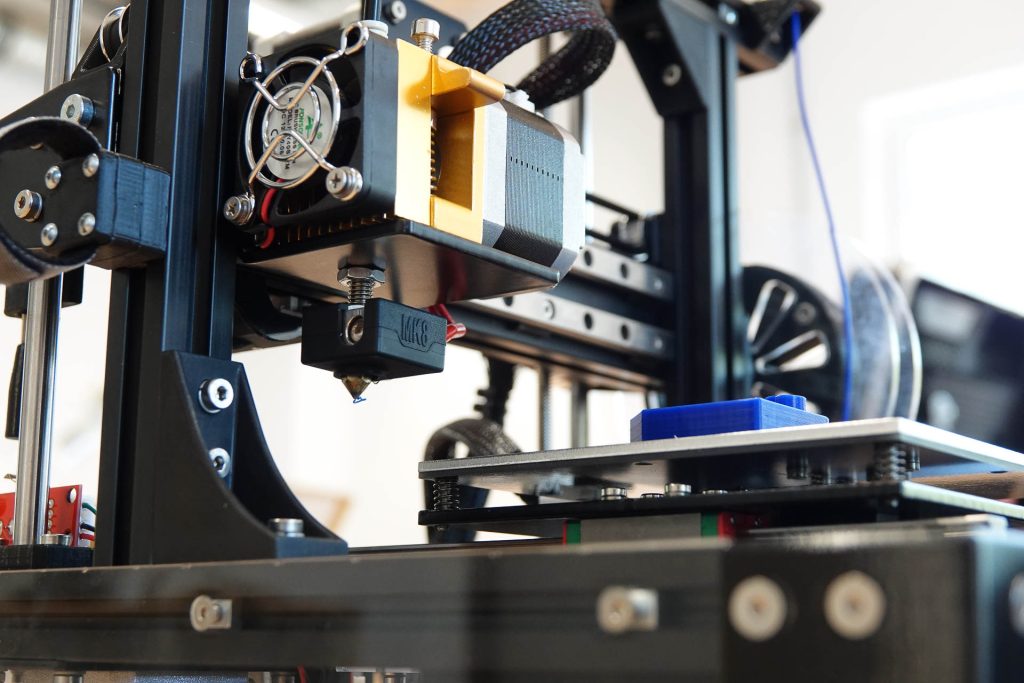

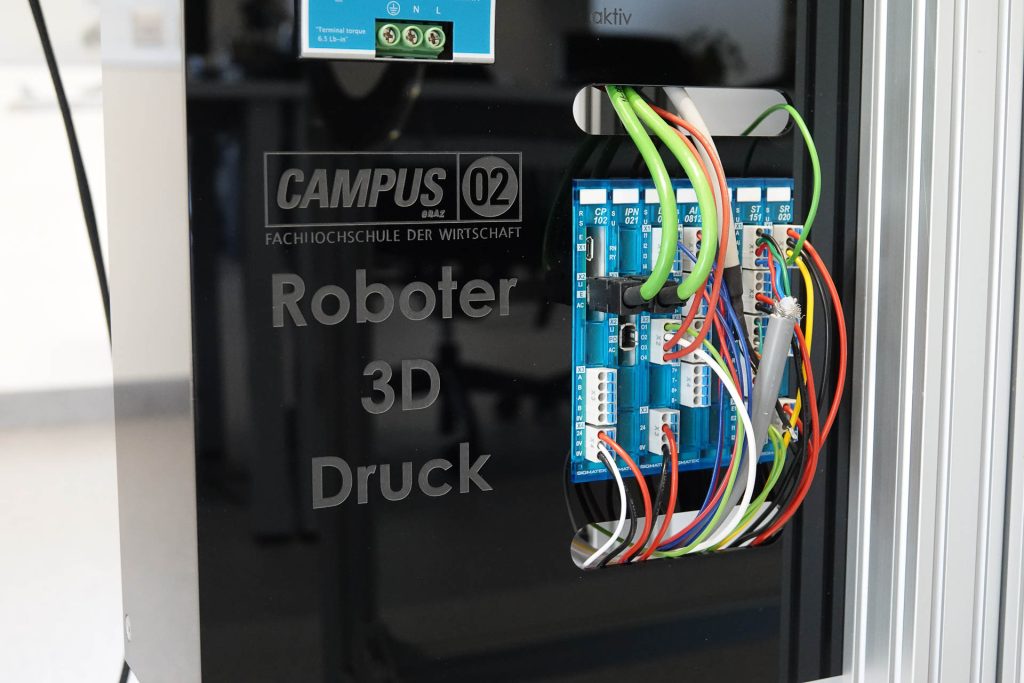

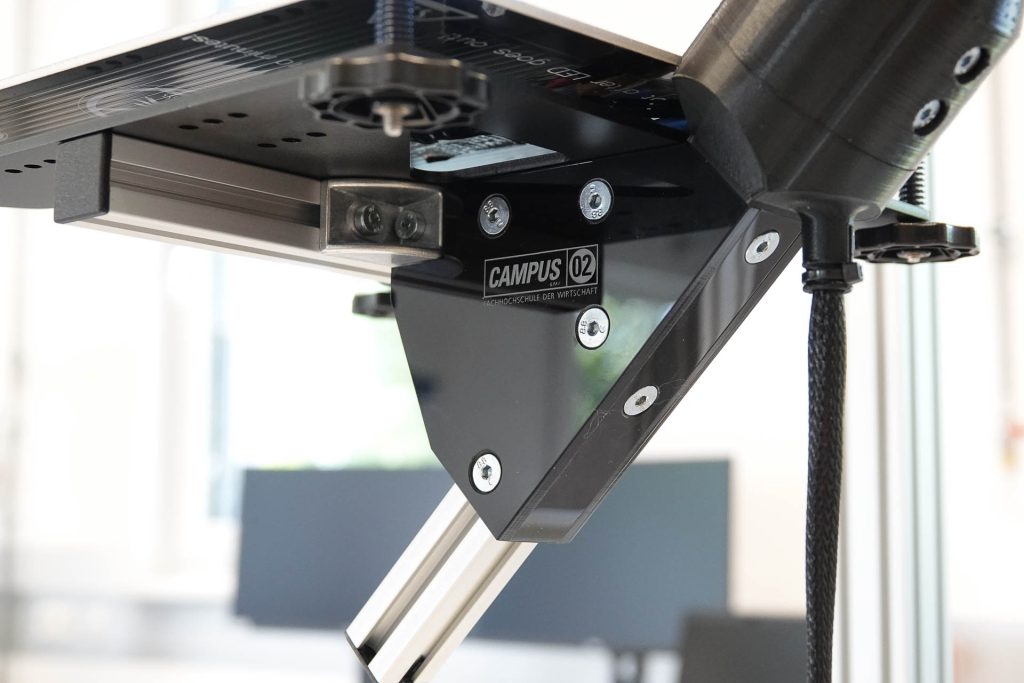

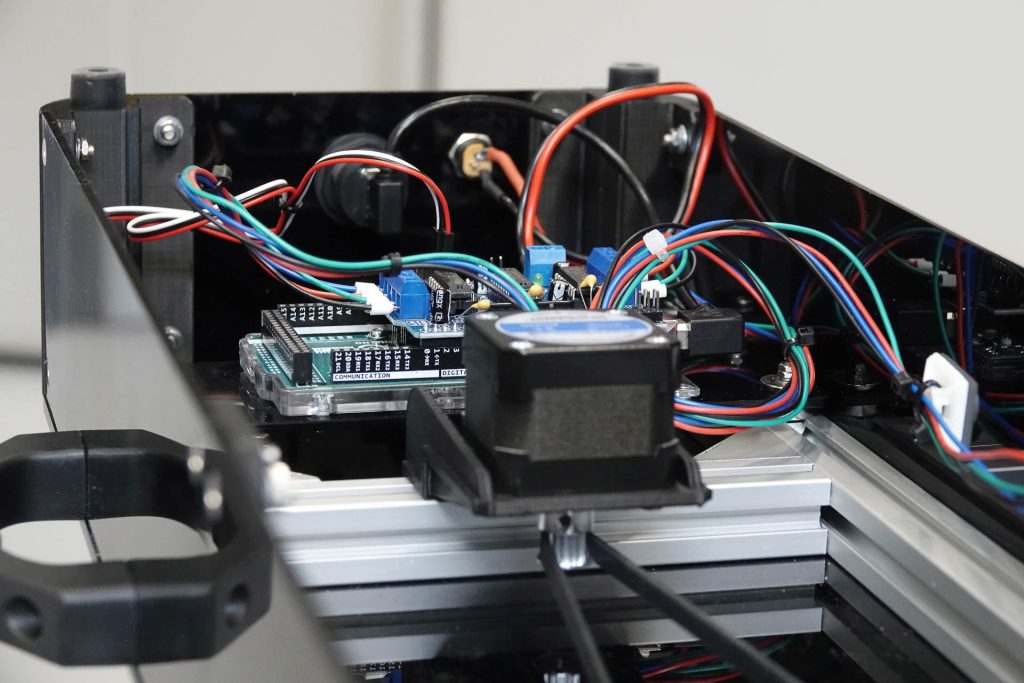

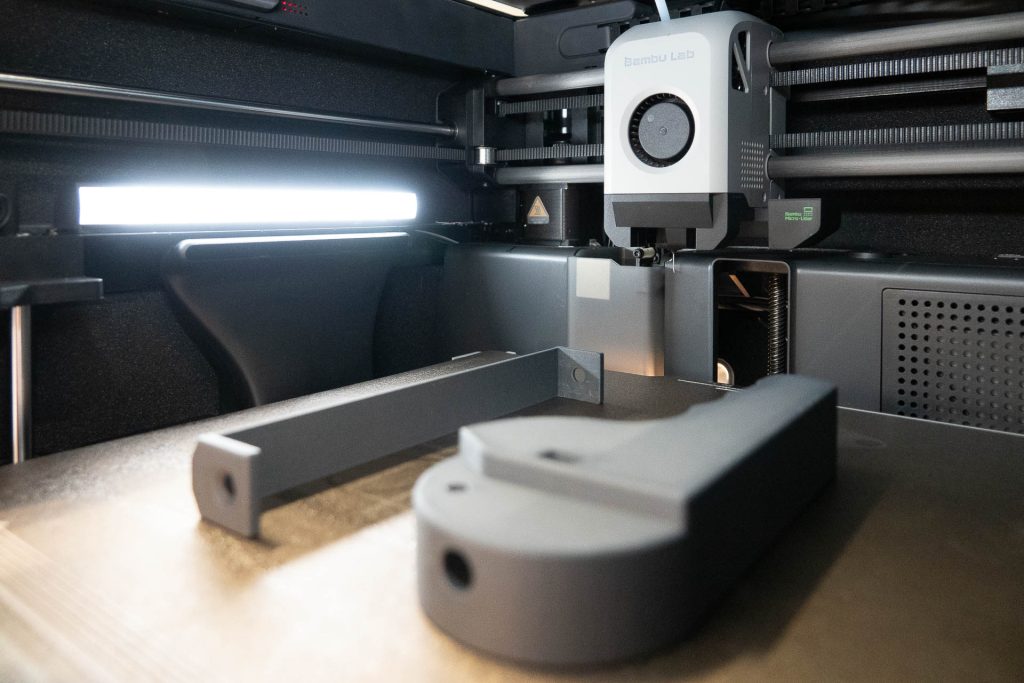

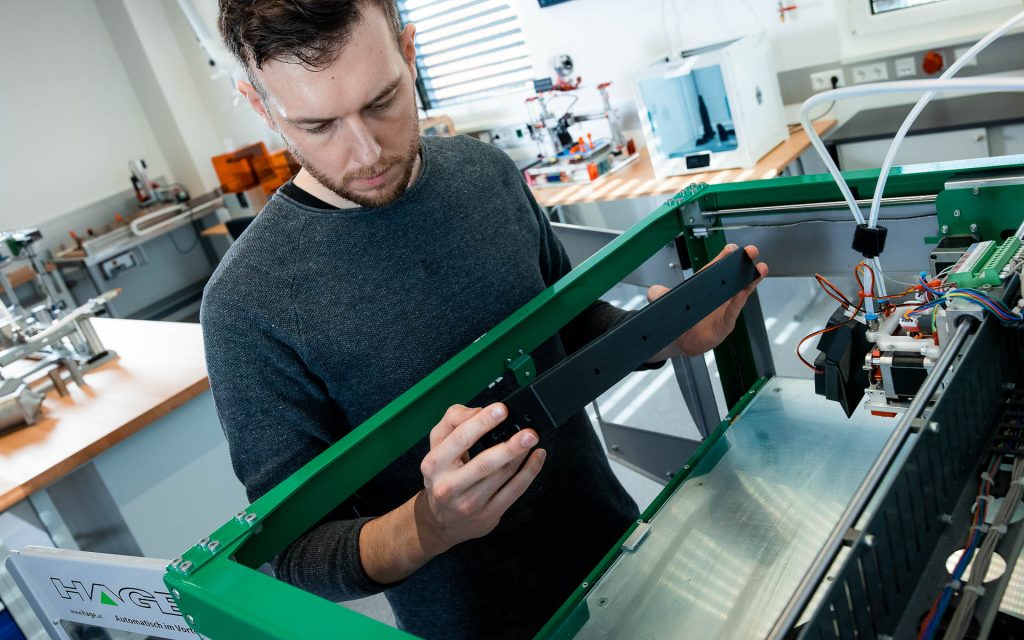

Since 2010, the Department Automation Technology at CAMPUS 02 UAS has been operating a Rapid Prototyping Lab equipped with various additive manufacturing techniques to support prototype development and specific problem-solving. Spanning 90 m², the lab features state-of-the-art technologies for Rapid Prototyping and Additive Manufacturing, suitable for both scientific and industrial applications. The expertise specifically covers process-specific know-how for generative manufacturing technologies such as Fused Filament Fabrication (FFF/FDM/FLM), Stereolithography (SLA/STL), 3D Printing (3DP), and Selective Laser Sintering (SLS).

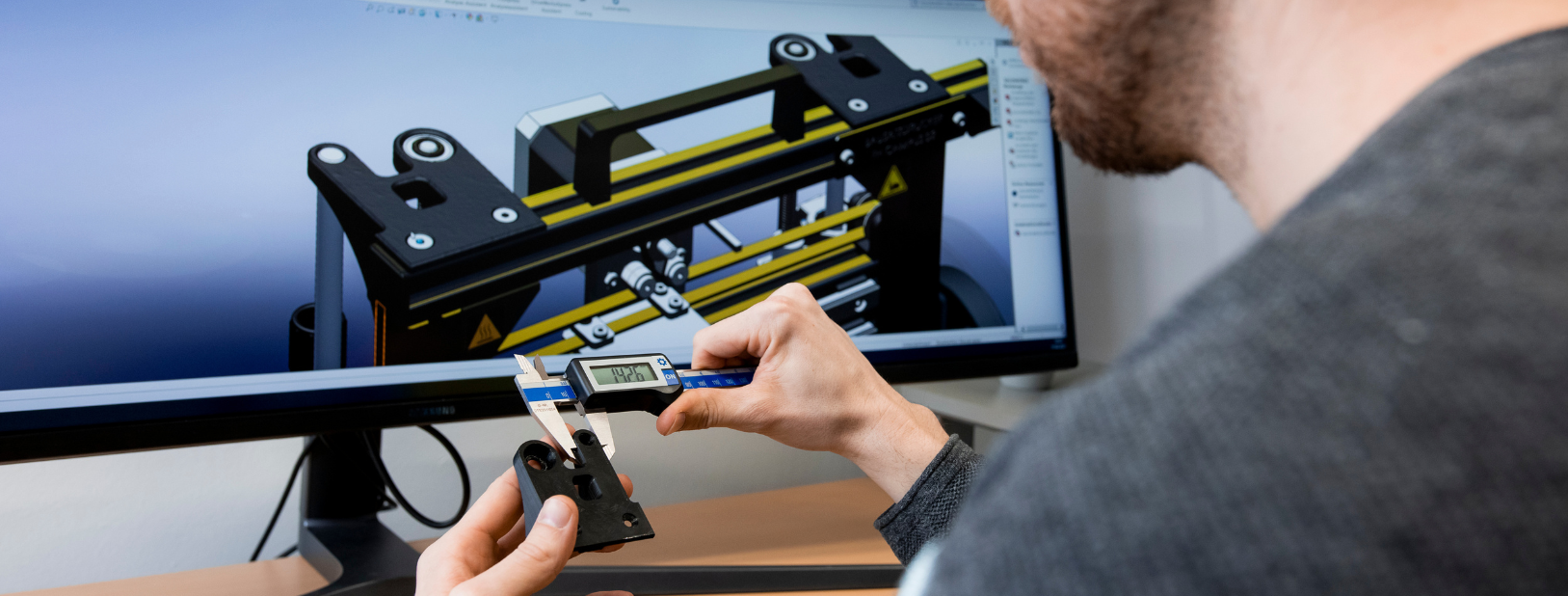

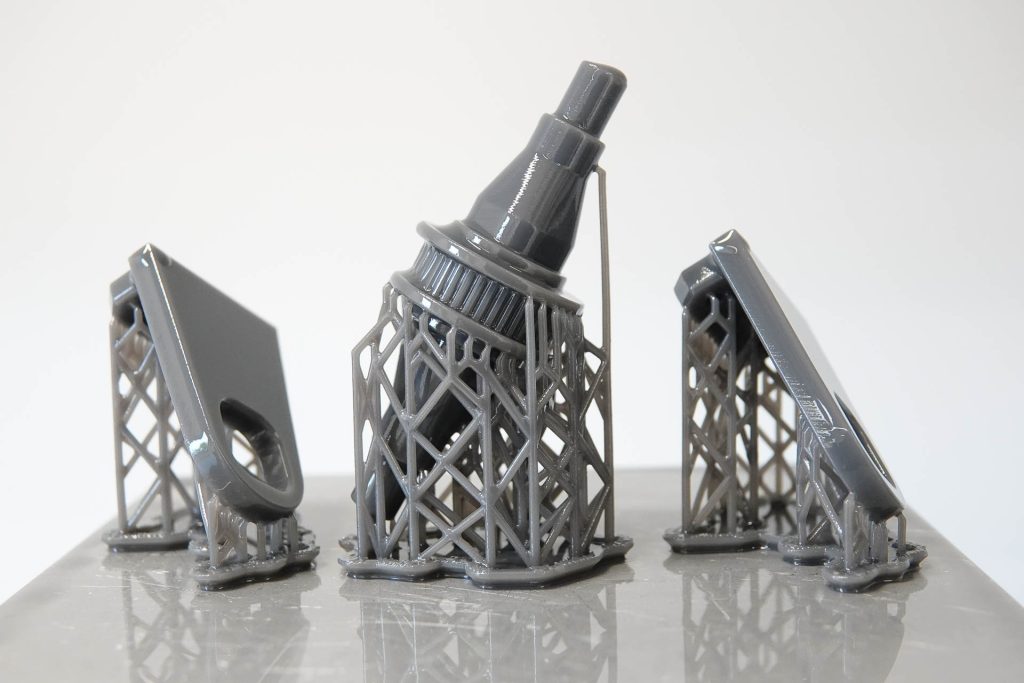

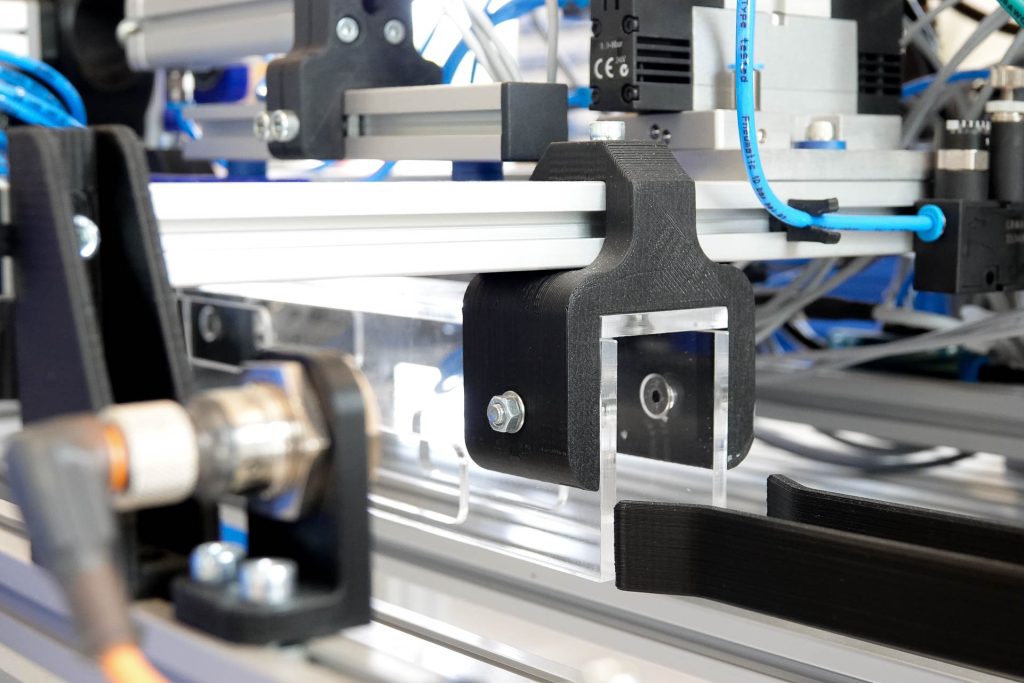

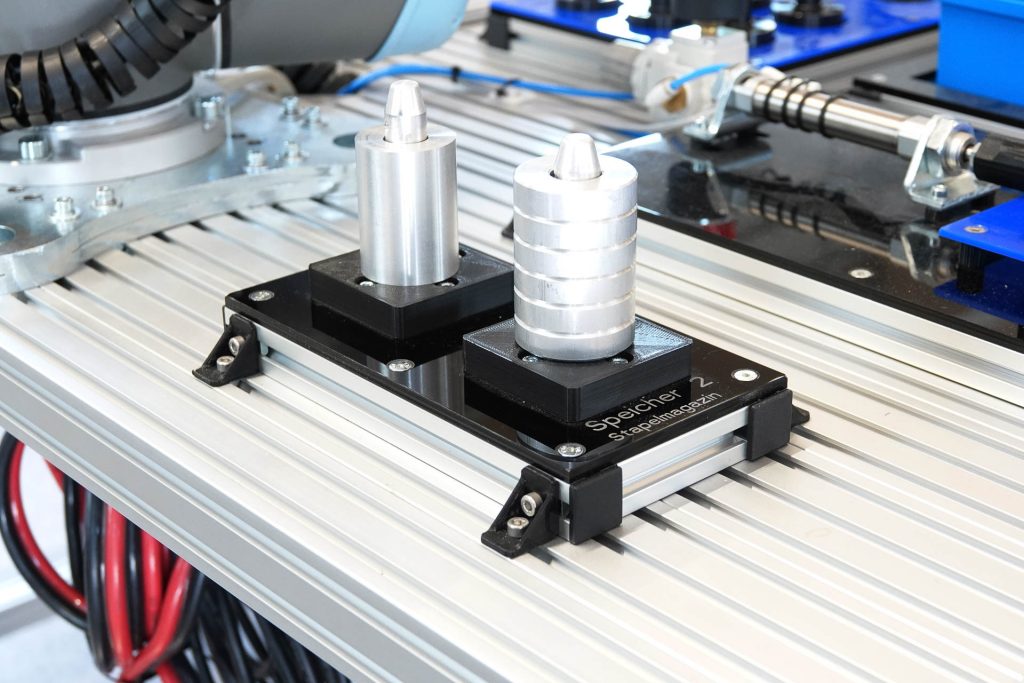

A key focus in the context of the comprehensive implementation process, from concept to component, is the design and optimization of parts to fully leverage the advantages of additive manufacturing. We are pleased to support you in this area. In various projects, specialists successfully apply these technologies in combination with traditional manufacturing methods, exploring their limitations and further developing them through collaborative research. Function integration and technology-appropriate complexity enhancement are used to exploit the potential of additive manufacturing processes.

Rapid prototyping offers great potential for increasing competitiveness through:

If you are interested but unsure which 3D printing method would be optimal for your specific application, or if you are uncertain whether 3D printing is feasible and worthwhile for your case, or if you need assistance with 3D modeling and design, please do not hesitate to contact us.

CAMPUS 02 University of Applied Sciences

Department Automation Technology

Körblergasse 126, 8010 Graz