Main research areas

When conducting research and development projects, the focus is on a holistic approach to the issue at hand and an interdisciplinary solution.

The research and development topics in the Department Automation Technology are dominated by the six areas described below:

- Industrial measurement technology and test bench automation

- Virtual methods and simulation in the development of mechatronic systems

- Product, process and system development

- Process optimisation using wireless communication technologies

- Optimisation of electrical energy efficiency and self-sufficiency

- Development of prototypes and demonstrators

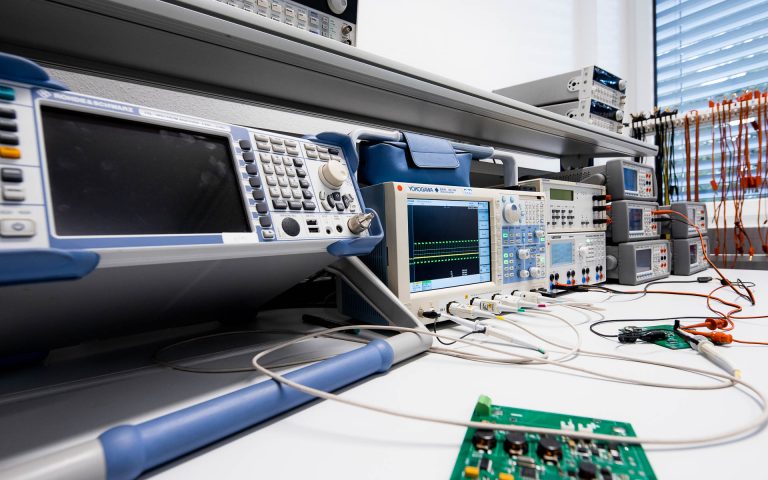

For such inquiries, the fully equipped Electronic Engineering and Assembly Lab is available. In addition to a wide range of electronic measuring equipment, it includes a thermostream (-80 °C to +250 °C), a temperature chamber and a cllimate chamber. The lab's equipment covers a broad spectrum of different measurement methods and also enables high-frequency measurements up to the GHz range (DC to 3 GHz).

The services offered are primarily aimed at innovative companies with extensive measurement and testing requirements in quality assurance.

The challenge in applying virtual methods and simulations in development lies in the ability to simulate and optimize the function and behavior of components, devices, and even entire factory systems during the design and development phases.

In addition to mechanical engineering and electrical engineering, simulation models and digital twins are increasingly applied in the field of energy technology. Here, calculation models are used to simulate energy generation, storage, and consumption as a means to efficiently network various systems. Through intelligent controllers based on machine learning and predictive models, energy systems are further optimized, and research is conducted to find future solutions for the upcoming energy transition.

3D models of products, as well as complex systems and process simulations, are visualized and virtually validated during the design phase—often using a VR headset. This approach not only allows for quick ergonomic checks but also enhances the ability to visualize and understand the designs better.

Virtual Reality tools are also used for the active control and visualization of laboratory infrastructure. For example, in the VR lab of the Energy Analytics and Solution Lab, a VR headset allows users to control both their own lab and the partner lab in Kapfenberg. Additionally, the VR headset provides many other innovative possibilities, from data visualization to virtual lab tours.

Through the interdisciplinary collaboration of all our departments, we support companies that aim to both optimize their products and ensure high quality. Our range of cooperation partners extends from manufacturing companies and firms with their own design departments to manufacturers of mechatronic systems.

The Department Automation Technology offers partner companies comprehensive support in product and process development, extending to the design and development of entire systems.

In initial consultation meetings, the requirements and goals of partner companies are outlined, defined, and subjected to a requirements analysis. The conceptualization and development of solutions in product, process, and system development follow a holistic and interdisciplinary approach to problem-solving and implementation.

The core element of this approach is the interplay between the fields of electronics, computer science, mechanical engineering, control engineering, and energy technology.

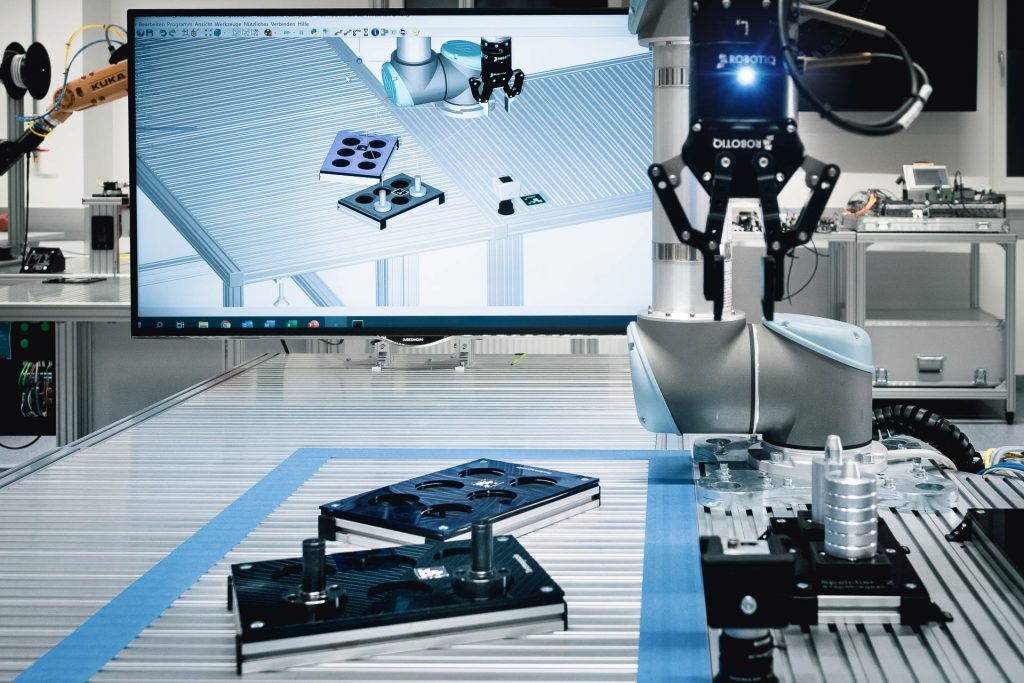

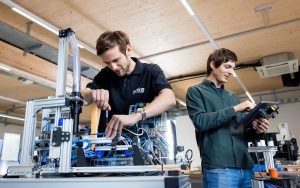

To investigate automated process flows and process and system developments in the field of handling technology, the Mechanical Engineering and Robotics Lab has, among other equipments, two industrial robots from the company Kuka and a collaborative robot from Universal Robots at its disposal.

An omnipresent question in research and development at CAMPUS 02 University of Applied Sciences is how to save energy by utilising synergies.

In most companies and facilities, a variety of mechatronic systems often operate independently of each other. By integrating the capabilities of mechanical engineering, electrical engineering, and computer science, and through the use of intelligent measurement, control, and regulation technology, energy savings are achieved, peak loads are avoided, and network quality is improved.

The laboratory not only supports internal and cooperatively funded research and development efforts but also serves as a point of contact for businesses in Styria for contract research and development activities. In the context of volatile energy supplies, grid operation modes, customer expectations, and technical and regulatory constraints, the EAS-Lab provides the necessary conditions to transform opinions into arguments and problems into solutions. Thus, the laboratory is a crucial component for developing future technologies and strategies, as well as for optimization steps towards implementing the energy transition.

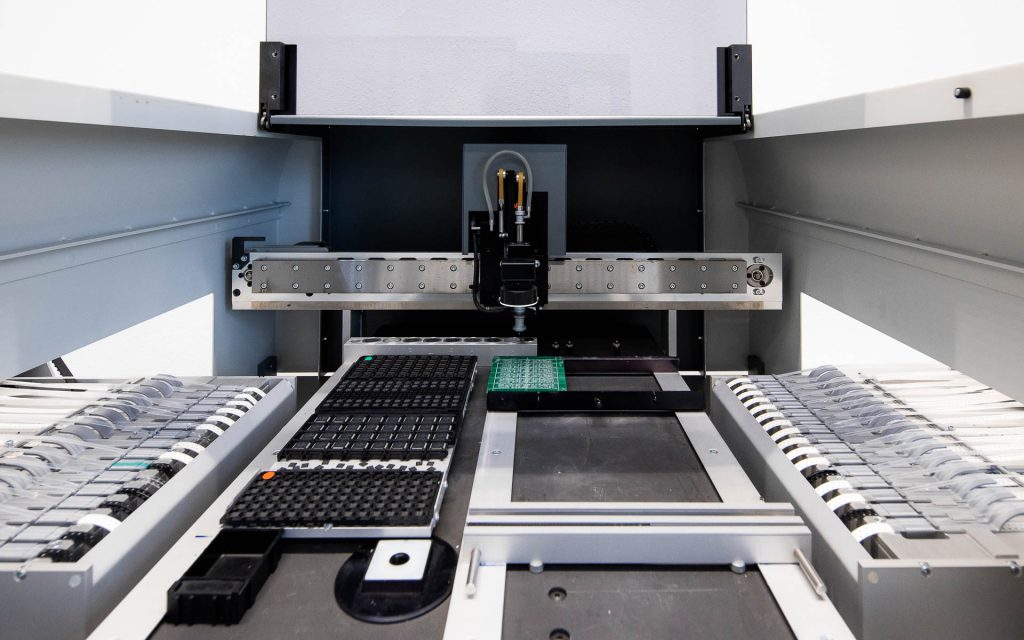

In addition to SPICE simulation of circuits, the electronics developed in the Electronic Engineering and Assembly Lab can be manufactured as prototypes or in small series. For the production, assembly, and post-processing of the corresponding PCBs, the lab is equipped with a range of tools, including a solder paste application table, a semi-automatic assembly table, an SMD placement machine, a vapor phase soldering oven, and a rework station.

This production line and the wide range of processing options form the basis for the efficient production and targeted optimisation of microelectronic solutions (such as circuit boards).

The mechanical construction and implementation of functional models for process development take place in the in-house Rapid Prototyping Lab and the Mechanical Engineering and Robotics Lab. This provides companies and educational institutions the opportunity to transform their ideas and visions into tangible prototypes. Form, color, and structure can be tested during development using a rapid prototyping model. Various additive manufacturing methods, an ATOS 3D scanner for reverse engineering applications, and a Trotec laser engraving machine with 60 W laser power are available for this purpose.

The core of the prototypes typically consists of project-specific firmware developed and tested in-house. The software implementation and commissioning of functional models are carried out in close collaboration among the involved departments.

Contact for further information

CAMPUS 02 University of Applied Sciences

Department Automation Technology

Körblergasse 126, 8010 Graz

CAMPUS 02

CAMPUS 02 University of Applied Sciences

Department Automation Technology

Körblergasse 126, 8010 Graz

Follow us on:

- +43 316 6002-8916

- thomas.thiebet@campus02.at

- Raumnummer: CR 236

- +43 316 6002-172

- rene.kerschbaumer@campus02.at

- Raumnummer: CZ 201a