Mechnical engineering

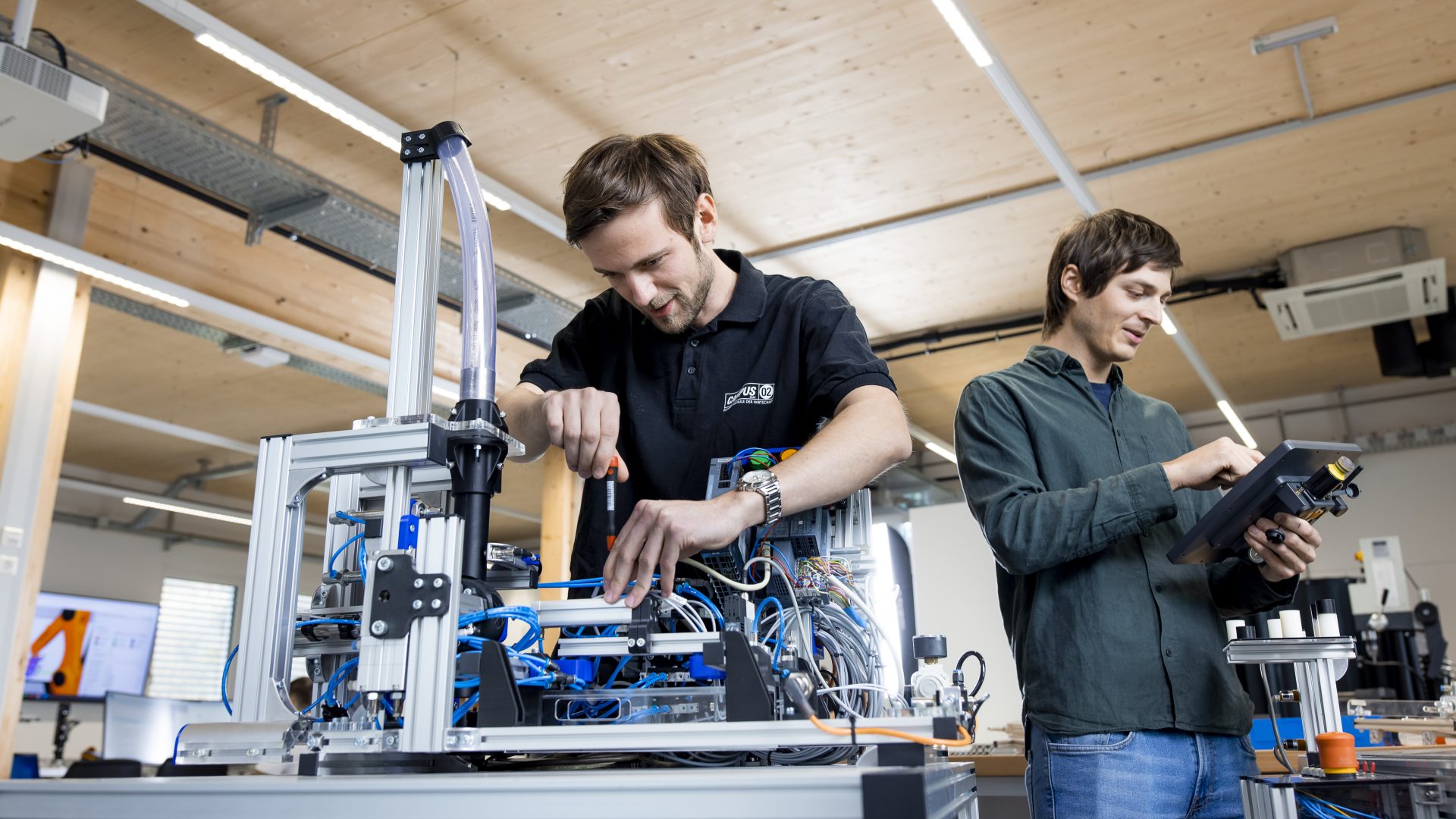

For example, in product development, the strength and topology of components and assemblies are simulated and subsequently optimized. The potential of additive manufacturing processes is leveraged through functional integration and technology-appropriate complexity enhancement. In process and system development, the digital twin, in various forms, and virtual commissioning are used—alongside state-of-the-art methods—to increase efficiency, improve the quality of solutions, and shorten the development time to the physical functional prototype. Additionally, modern methods can also be employed to safeguard the development process itself.

The entire product, system, and process development is carried out in the context of the Digital Factory. By utilizing virtual reality (VR) and augmented reality (AR) methods, we create interactive virtual environments, such as laboratory spaces and presentation rooms, which are used for training purposes and to provide a realistic experience of virtual project outcomes. Additionally, virtual content is integrated with real-world elements in real-time. The bidirectional data exchange significantly expands the range of possible applications. Virtual reality applications are further enhanced by layout planning, ergonomics checks, and functional design. With this range of services, we successfully support companies in addressing various challenges and at different stages of development.

If you have any questions regarding mechanical engineering or a specific project in mind, we’d be delighted to hear from you. FH-Prof. DI Dr. techn. Christian Gasser is available to provide expert guidance and support for your endeavors.

Contact for further information

CAMPUS 02 University of Applied Sciences

Department Automation Technology

Körblergasse 126, 8010 Graz

Contact for further information

CAMPUS 02 University of Applied Sciences

Department Automation Technology

Körblergasse 126, 8010 Graz

Follow us on:

- +43 316 6002-8118

- christian.gasser@campus02.at

- Raumnummer: CR 337

- +43 316 6002-172

- rene.kerschbaumer@campus02.at

- Raumnummer: CZ 201a